Explore cut & sew manufacturing for streetwear and why customization matters for brand identity, quality control, and market differentiation in the competitive fashion industry. Cut & sew manufacturing represents the highest level of customization in apparel production, allowing brands to create unique garments from scratch rather than using pre-made blanks. For streetwear brands, this approach offers significant advantages in brand identity, quality control, and market differentiation.

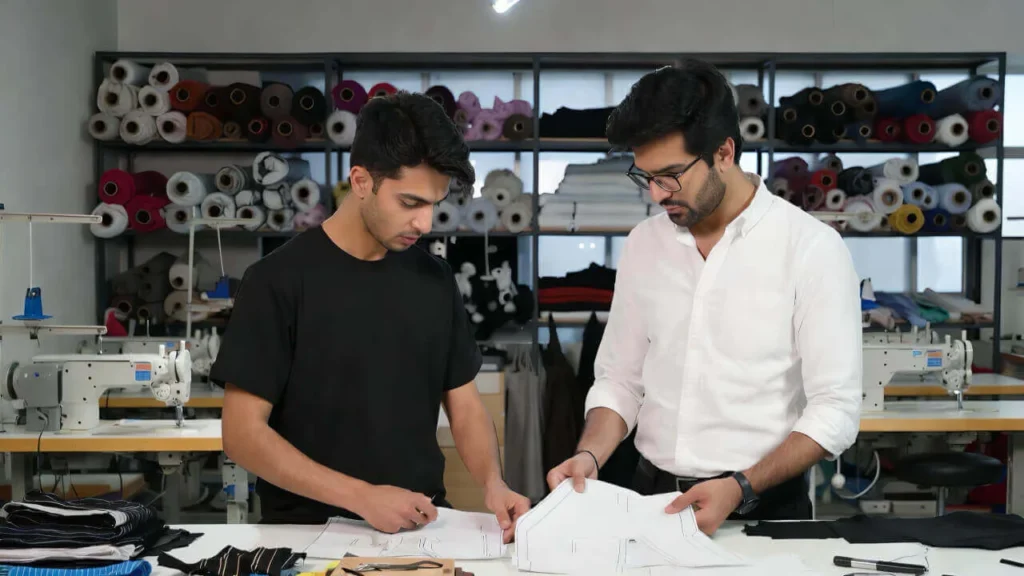

What is Cut & Sew Manufacturing? Cut & sew involves creating garments entirely from raw materials rather than using pre-made blanks. The process includes:

· Pattern making: Creating templates for each garment component

· Fabric cutting: Precision cutting of pattern pieces from fabric rolls

· Sewing operations: Assembling pieces into finished garments

· Quality control: Inspecting at various stages for consistency

This approach contrasts with using pre-made blanks that are then customized with prints or embroidery. Cut & sew allows complete control over every aspect of the garment from fit to fabric selection.

Benefits of Cut & Sew for Streetwear Brands Complete design freedom is the primary advantage of cut & sew manufacturing:

· Unique silhouettes: Creating distinctive shapes not available elsewhere

· Custom fabrics: Selecting or developing exclusive materials

· Signature details: Incorporating unique design elements and features

· Brand identity: Establishing recognizable aesthetic through garment construction

Quality control is significantly enhanced with cut & sew:

· Material selection: Choosing quality fabrics appropriate for each design

· Construction control: Specifying stitching types and reinforcement points

· Consistency: Maintaining standards across production runs

· Durability: Building garments to withstand wear and washing

Brand differentiation through cut & sew helps streetwear brands stand out:

· Exclusive designs: Offering products

not available through blank customization

· Perceived value: Customers recognize and appreciate fully custom garments

· Price positioning: Commanding premium prices for unique products

· Design protection: Difficulty in replicating fully custom designs

Challenges and Considerations Higher minimums are typically required for cut & sew compared to blank customization:

· Development costs: Pattern making and sampling require investment

· Material sourcing: Finding appropriate fabrics in minimum quantities

· Production complexity: Managing multiple components and processes

· Expertise requirement: Technical knowledge needed for garment engineering

Longer development timeline is another consideration:

· Sampling process: Multiple iterations may be needed to perfect designs

· Production planning: More complex coordination required

· Quality assurance: Additional steps needed to maintain standards

Finding the Right Manufacturing Partner Experience with streetwear is crucial when selecting a cut & sew manufacturer:

· Understanding of aesthetic: Familiarity with streetwear styles and details

· Technical capability: Ability to execute complex designs and constructions

· Quality standards: Commitment to consistent high-quality production

· Communication: Responsive and clear throughout development process

MOQ flexibility is important for growing brands:

· Gradual scaling: Ability to increase quantities as business grows

· Style minimums: Reasonable requirements for new designs

· Production planning: Flexibility in scheduling and order timing

The Cut & Sew Development Process Design development transforms concepts into producible garments:

· Technical sketches: Detailed drawings with measurements and details

· Pattern making: Creating paper or digital patterns for each component

· Sample making: Producing prototypes for fit and design evaluation

· Fit sessions: Evaluating samples on models for adjustments

Production planning ensures smooth manufacturing:

· Fabric sourcing: Selecting and testing appropriate materials

· Grading: Creating size ranges based on approved sample

· Marker making: Optimizing fabric layout to minimize waste

· Production scheduling: Coordinating with manufacturer capacity

Quality assurance maintains standards throughout production:

· In-process inspection: Checking during various production stages

· Final inspection: Comprehensive review of finished garments

· Testing: Laboratory tests for fabric performance and durability

Conclusion

Cut & sew manufacturing offers streetwear brands unparalleled design freedom, quality control, and brand differentiation. While requiring greater investment and expertise than blank customization, the benefits for establishing distinctive brand identity and producing premium products make it worthwhile for serious streetwear labels.