Discover the science behind moisture-wicking fabrics including how they work, different technologies, performance testing, and applications for activewear and sportswear.

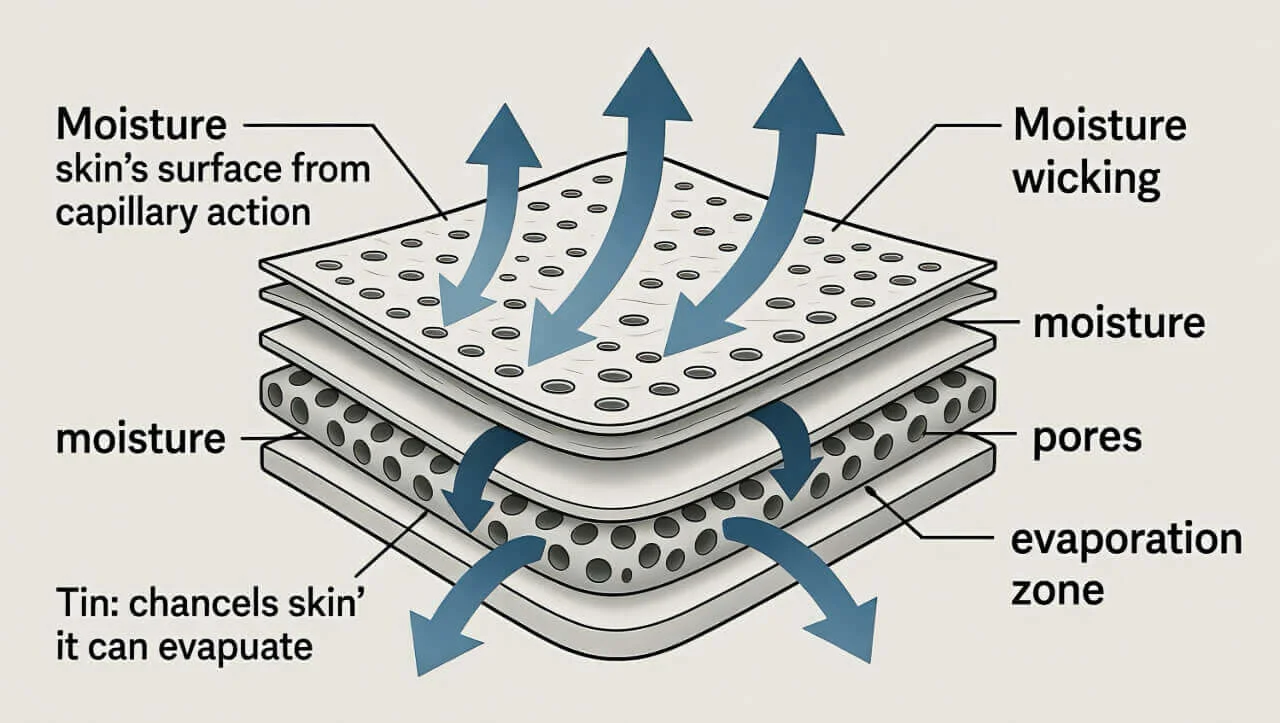

Moisture-wicking fabrics are essential for activewear and performance apparel, keeping wearers dry and comfortable during physical activity. These technical fabrics use advanced science to move moisture away from the skin to the fabric surface where it can evaporate quickly.

· Micro-channels: Fibers with grooves or channels that pull moisture along

· Cross-section design: Engineered fiber shapes that enhance wicking

· Surface tension: Physics principles moving moisture from areas of higher to lower concentration

Hydrophilic vs. hydrophobic properties are manipulated in wicking fabrics:

· Hydrophilic areas: Attract and pull moisture through the fabric

· Hydrophobic areas: Repel moisture and facilitate quick drying

· Dual-layer fabrics: Hydrophilic inside, hydrophobic outside systems

Yarn engineering creates enhanced wicking capabilities:

· Micro-denier fibers: Finer fibers creating more surface area for wicking

· Specialty spins: Engineered yarn structures with enhanced properties

· Blend optimization: Combining fibers with different properties

Types of Moisture-Wicking Fabrics Synthetic performance fabrics dominate the moisture-wicking category:

· Polyester: Most common wicking fiber with excellent durability

· Nylon: Strong and abrasion-resistant with good wicking properties

· Polypropylene: Excellent moisture movement but less common in apparel

· Specialty synthetics: Advanced fibers with enhanced wicking capabilities

Natural fiber blends incorporating wicking technologies:

· Merino wool: Natural wicking properties and odor resistance

· Cotton blends: Combining comfort with wicking performance

· Bamboo blends: Softness with moisture management properties

Fabric constructions enhancing wicking performance:

· Knit structures: Engineered patterns optimizing moisture movement

· Mesh panels: Strategic placement for enhanced ventilation

· Double-layer constructions: Separate inner and outer functions

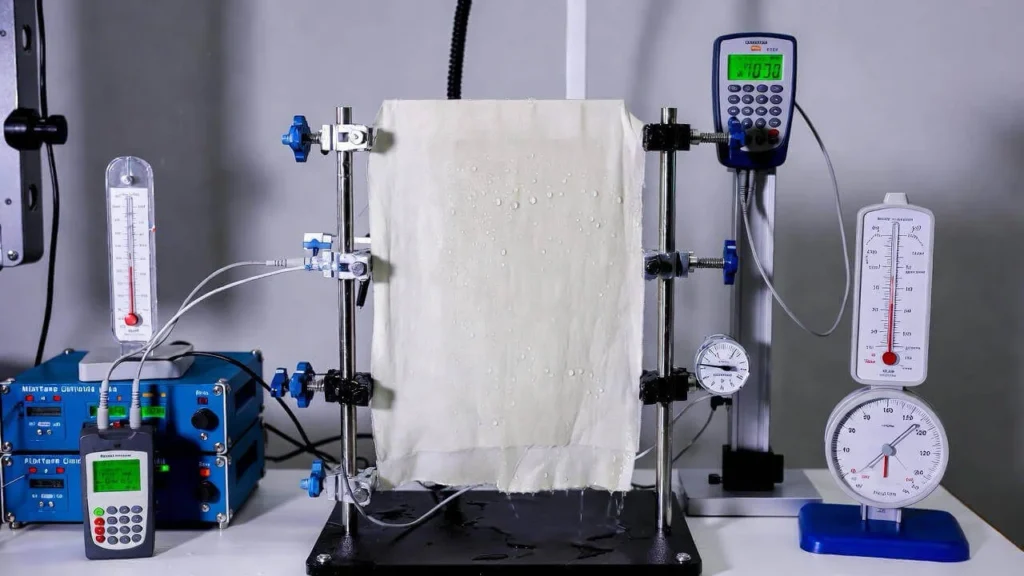

Performance Testing and Standards Laboratory testing measures moisture-wicking performance:

· Vertical wicking test: Measures how high moisture travels up a fabric strip

· Absorption rate: How quickly fabric absorbs moisture

· Drying time: How quickly fabric releases moisture to environment

· Moisture vapor transmission: Rate of vapor passing through fabric

Standardized test methods provide comparable results:

· AATCC 79: Absorption rate of textiles

· ISO 9073-6: Absorption time and water absorption capacity

· ASTM D737: Air permeability of textile fabrics

Performance standards help consumers identify effective products:

· Brand-specific standards: Companies develop their own testing protocols

· Third-party certifications: Independent verification of claims

· Comparative ratings: Systems ranking products by performance

Applications in Activewear and Sportswear Sport-specific applications optimize wicking performance:

· Base layers: Direct skin contact for maximum moisture management

· Compression wear: Tight-fitting garments with enhanced wicking

· Climate-specific designs: Different weights for various conditions

· Layering systems: Coordinated pieces working together

Comfort enhancements through moisture management:

· Temperature regulation: Evaporation cooling during activity

· Reduced chafing: Dry fabric reducing friction against skin

· Weight management: Preventing waterlogged heavy garments

· Quick recovery: Faster drying between activities or washes

Innovations and Future Developments Smart moisture management represents the future of wicking fabrics:

· Adaptive technologies: Responding to changing conditions

· Phase change materials: Absorbing and releasing heat as needed

· Microencapsulation: Incorporating active ingredients into fibers

· Biomimicry: Learning from natural systems like leaf structures

Sustainability initiatives in moisture-wicking fabrics:

· Recycled materials: Using post-consumer plastic bottles

· Bio-based synthetics: From renewable sources rather than petroleum

· Green chemistry: Environmentally friendly treatments and processes

· Circular design: Recyclable or biodegradable at end of life

Conclusion

Moisture-wicking fabrics represent sophisticated textile technology combining fiber engineering, fabric construction, and finishing treatments. Understanding the science behind these fabrics helps brands select appropriate materials for their activewear and sportswear products, ensuring performance meets customer expectations.